Desilter in Solids Control Systems

In modern drilling operations, fluid performance directly impacts safety, efficiency, and overall project cost. As wells become deeper and more complex, controlling ultra-fine solids in drilling mud has become more critical than ever. This is where the desilter in solids control systems plays a vital role.

During drilling, large volumes of drilled cuttings and fine particles continuously enter the mud system. While shale shakers and desanders remove coarse solids, they are not capable of eliminating ultra-fine particles. If left untreated, these solids reduce mud performance, increase wear on equipment, and significantly raise operational costs.

A properly designed desilter in solids control systems ensures cleaner drilling fluids, extended equipment life, and improved drilling efficiency across global oil and gas operations.

What Is a Desilter in Solids Control Systems?

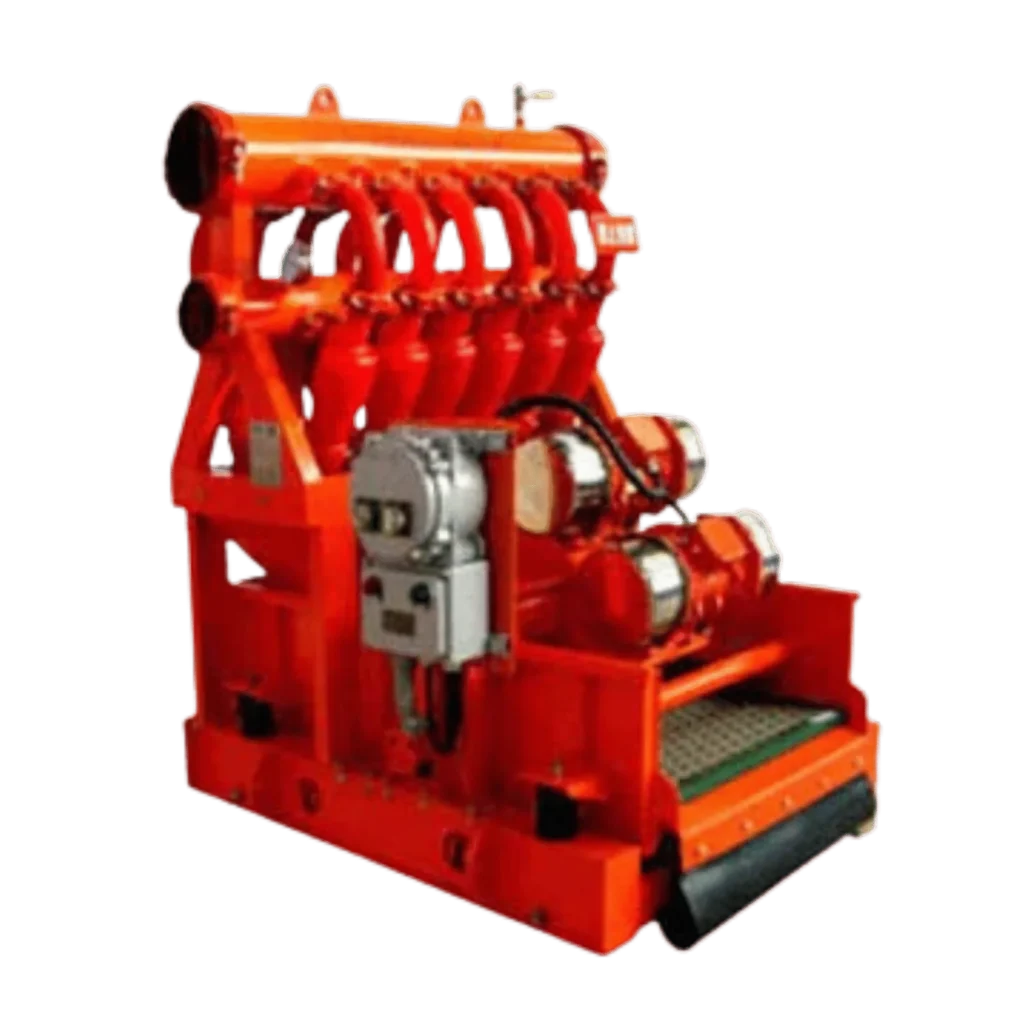

A desilter in solids control systems is a secondary-stage separation device installed after the desander. It uses multiple small-diameter hydrocyclones to remove ultra-fine solids typically ranging between 15 and 45 microns.

By applying centrifugal force, the desilter separates fine particles from the drilling fluid before they can damage pumps, bits, and downhole tools. This process maintains mud properties within required specifications and ensures continuous fluid reuse.

Because of its efficiency, the desilter has become an essential component of modern drilling fluids solids control systems used worldwide.

Why a Desilter Is Essential in Drilling Operations

As drilling progresses, fine solids gradually accumulate in the mud system. These particles are difficult to remove using conventional equipment. Without a desilter, fine solids can:

Increase mud density unnecessarily

Reduce penetration rate

Cause excessive abrasion to pumps and valves

Lead to higher chemical treatment costs

Installing a desilter for oil and gas rigs ensures stable mud properties and reduces non-productive time (NPT). This is especially critical in high-cost drilling environments such as offshore, geothermal, and deep wells.

A high-quality oilfield desilter equipment setup helps operators maintain consistency even under extreme drilling conditions.

Key Features of a High-Performance Desilter

Modern desilters are engineered for durability, accuracy, and easy integration. A well-designed desilter in solids control systems typically includes:

Fine solids separation between 15–45 microns

High-performance hydrocyclone cones for consistent output

Abrasion-resistant polyurethane or ceramic linings

Modular compact design for limited rig space

Customizable cone configurations based on flow rate

Low maintenance structure with replaceable liners

These features allow the desilter to operate continuously with minimal downtime, making it ideal for both onshore and offshore drilling operations.

Technical Specifications Overview

A standard API compliant desilter is designed to operate efficiently across varying flow rates and drilling conditions. Typical specifications include:

Cone Diameter: 4″ standard (5″ or 6″ optional)

Operating Capacity: 50–60 GPM per cone

Particle Removal Range: 15–45 microns

Working Pressure: 0.25–0.4 MPa

Flow Capacity: 500–1500 GPM

Cone Quantity: 8–20 cones

Connection Type: Flanged or threaded

Compliance: Meets API and international standards

These specifications ensure smooth integration into existing drilling fluids solids control systems.

Top 7 Benefits of Using a Desilter in Solids Control Systems

1. Improved Mud Quality

The desilter efficiently removes fine solids that negatively affect rheology and filtration properties.

2. Reduced Mud Treatment Costs

Cleaner mud requires fewer chemicals, resulting in lower overall operating expenses.

3. Extended Equipment Life

By removing abrasive particles, the desilter protects pumps, motors, and drilling tools.

4. Enhanced Drilling Efficiency

Stable mud properties improve penetration rate and drilling performance.

5. Lower Environmental Impact

Reduced waste volume supports environmentally responsible drilling practices.

6. Improved Fluid Reusability

The system allows mud to be recycled multiple times without quality loss.

7. Consistent Performance in Complex Wells

A reliable desilter for oil and gas rigs performs effectively in CBM, geothermal, and offshore wells.

Applications Across the Oil & Gas Industry

The desilter in solids control systems is widely used in:

Onshore drilling operations

Offshore oil and gas rigs

Integrated mud systems

Coal Bed Methane projects

Geothermal drilling

Mud recycling and circulation units

Its adaptability makes it a critical component of modern oilfield desilter equipment worldwide.

Why Choose Petropath Desilters?

Petropath designs and manufactures advanced oilfield desilter equipment built for global drilling operations. Each unit is engineered with high-grade materials, precision hydrocyclones, and strict quality control.

Key advantages include:

API-tested equipment

Long-lasting polyurethane and ceramic components

Custom-built configurations

Strong technical and after-sales support

Suitable for land and offshore rigs

The focus remains on reliability, durability, and long-term operational value.

Conclusion

The desilter in solids control systems is a cornerstone of efficient and cost-effective drilling operations. By eliminating ultra-fine solids, it ensures cleaner drilling fluids, extended equipment life, and improved drilling performance.

As drilling environments become more demanding, investing in a high-quality API compliant desilter is no longer optional—it is essential. With proper integration into drilling fluids solids control systems, operators can achieve higher efficiency, reduced risks, and sustainable operations across global oil and gas projects.

Looking for a reliable desilter in solids control systems for your drilling operations? Our technical experts are ready to help you choose the right configuration for your rig requirements.

Whether you need API compliant desilters, customized cone arrangements, or complete drilling fluids solids control systems, we provide solutions built for performance, durability, and global operations.