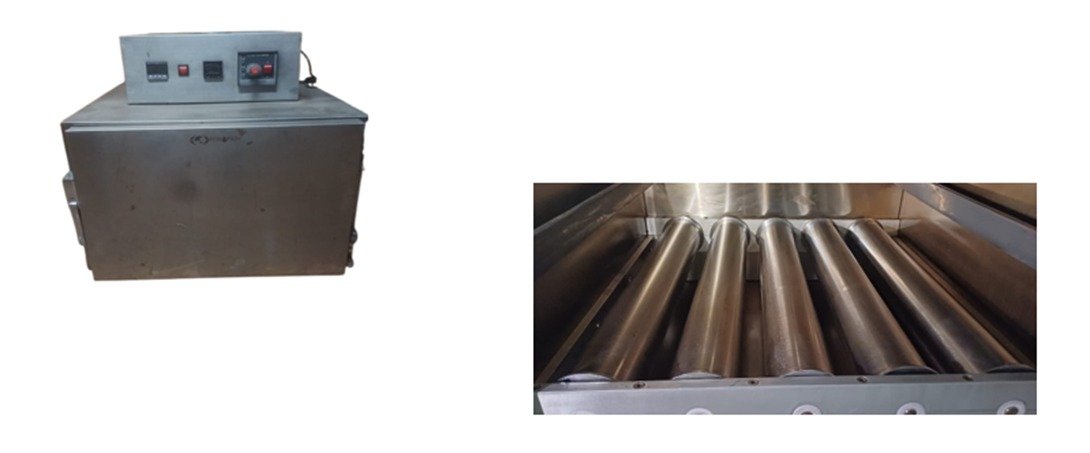

Purpose-Built Roller Oven for Oil & Gas Applications

Key Features of Petropath Roller Oven

- Precise Temperature Control

- Equipped with advanced thermostats and digital controllers.

- Capable of maintaining uniform heating across all samples.

- Continuous Rolling Mechanism

- Provides consistent rotation of sample cells.

- Ensures realistic simulation of drilling fluid movement in downhole conditions.

- Multiple Sample Capacity

- Available in configurations that hold 4, 6, or 8 cells simultaneously.

- Allows comparative testing of different mud formulations in one run.

- Durable Construction

- Built with heat-resistant alloys and rugged casing for long-term use.

- Designed to withstand laboratory and field-testing environments.

- Safety Features

- Over-temperature protection system.

- Insulated design to ensure operator safety during prolonged tests.

- Versatility

- Suitable for Oil-Based Mud (OBM), Water-Based Mud (WBM), and synthetic drilling fluids.

- Also used in cement slurry stability testing.

Why Roller Oven for Oil & Gas Applications Matters in Drilling Fluid Engineering

Using a Roller Oven for Oil & Gas Applications, laboratories can:

Predict fluid behavior under prolonged thermal exposure

Validate mud formulations before field use

Improve operational efficiency and drilling safety

This makes the roller oven a core component of drilling fluid testing equipment in oil and gas laboratories worldwide.

Key Advantages of Petropath Roller Oven for Oil & Gas Applications

🔹 Consistent Temperature Control

Precise temperature regulation ensures accurate and repeatable results across multiple test cycles, critical for reliable fluid analysis.

🔹 Dynamic Rolling Action

Continuous rotation mimics real downhole circulation, delivering realistic thermal aging for both water-based and oil-based mud systems.

🔹 Heavy-Duty Construction

Built for continuous laboratory operations, the roller oven withstands demanding oilfield testing environments.

🔹 Compatibility with Standard Aging Cells

The system supports industry-standard aging cells, making it easy to integrate into existing oil and gas laboratory equipment setups.

🔹 Safe & Insulated Design

Designed to meet oilfield HSE requirements, the insulated chamber enhances operator safety during high-temperature testing.

Applications of Roller Oven for Oil & Gas Applications

Thermal aging of drilling fluids

Mud formulation and optimization

High-pressure, high-temperature (HTHP) performance evaluation

Rheology and fluid loss analysis

Contamination and compatibility studies

These applications make the roller oven essential for comprehensive thermal aging of drilling fluids and long-term performance prediction.

Key Performance Features – Petropath Roller Oven for Oil & Gas Applications

| Specification | Petropath Advantage |

|---|---|

| Roller Assembly | Five SS 316 tubes, Ø7.5 cm × 60 cm, precision-balanced for vibration-free rotation |

| Sample Capacity | Eight 500 ml aging cells for accurate side-by-side comparisons |

| Rolling Speed | 25–50 rpm standard; optional digital speed variation available |

| Heating Element | 1000 W heating coil for rapid and uniform heat distribution |

| Working Temperature Range | 100–500 °F (38–260 °C), suitable for HP/HT testing |

| Insulation Accuracy | ±2 °F typical; ±5 °F during voltage fluctuations |

| Display & Redundancy | Digital PID controller with analog dial for fail-safe monitoring |

| Timer | Programmable up to 999 hours for long-duration aging studies |

| Duty Cycle | Continuous seven-day operation for uninterrupted testing |

| Power Supply | 230 V ±10%, 50 Hz ±1% for stable laboratory performance |

Supporting Efficient & Sustainable Drilling Operations

Accurate roller oven testing also supports environmentally responsible fluid design by:

Reducing excessive chemical usage

Preventing fluid breakdown and waste

Improving overall drilling sustainability

This aligns with the industry’s growing focus on safe, efficient, and environmentally conscious drilling practices.