Introduction

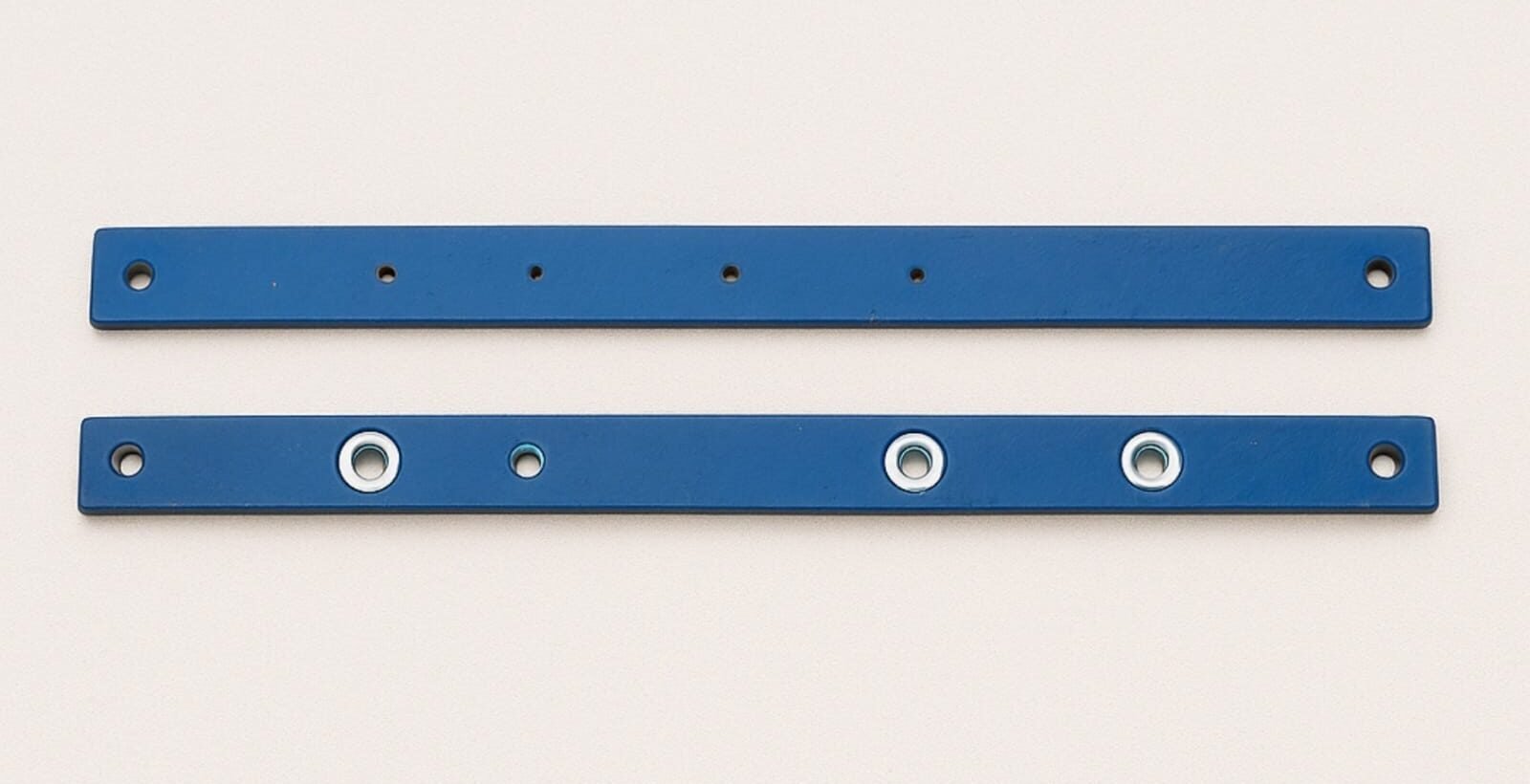

What Is a PU Strip for a Shale Shaker?

Key Functions of a Polyurethane Strip for Shale Shaker:

Absorbs vibration and impact loads

Prevents metal-to-metal contact

Secures shaker screens firmly

Eliminates drilling fluid bypass

Extends shale shaker screen life

Polyurethane is widely used in oilfield solids control equipment due to its exceptional abrasion resistance, elasticity, chemical stability, and long service life under extreme operating conditions.

Compatibility with All Major Shale Shaker Screen Types

Compatible With:

Derrick shaker screens

NOV Brandt shaker screens

SWACO shaker screens

Kemtron shaker screens

FSI shaker screens

Custom metal-backed and fabricated screens

Whether you operate flat screens, pyramid screens, or special metal-backed screens, our PU strip for shale shaker can be custom-manufactured to match exact dimensions and shaker models.

Why PU Strips Are Critical in Solids Control Systems

1. Extended Screen Life

A polyurethane strip for shale shaker cushions screens against continuous vibration, significantly reducing mesh fatigue, frame cracking, and premature failure.

2. Improved Sealing Efficiency

Accurate-fit shale shaker screen sealing strips prevent fluid bypass, ensuring that all drilling fluid passes through the screen for maximum solids removal.

3. Reduced Maintenance & Downtime

By protecting both the shaker basket and the screen frame, PU strips reduce replacement frequency, minimize repairs, and lower non-productive time (NPT).

4. Stable Shaker Operation

The vibration-dampening properties of a PU strip for drilling shale shaker promote smooth shaker motion even under high flow rates and heavy solids loading.

Key Features of Petropath PU Strips for Shale Shakers

High-grade polyurethane material

Superior abrasion and tear resistance

Excellent elastic recovery for vibration damping

Oil, chemical, and drilling mud resistant

Long operational life in harsh environments

Precision-cut for OEM and custom shaker screens

Each PU strip for shale shaker is manufactured under strict quality control to ensure consistent performance and dimensional accuracy.

Technical Specifications – PU Strip for Shale Shaker

| Parameter | Specification |

|---|---|

| Material | Polyurethane (PU) |

| Hardness | 70–90 Shore A (customizable) |

| Color | Yellow / Red / Black (custom options) |

| Operating Temperature | -40°C to +80°C |

| Chemical Resistance | Oil-based, water-based & synthetic muds |

| Abrasion Resistance | Excellent |

| Tensile Strength | High, suitable for high-G environments |

| Compatibility | All major shaker screen brands |

| Customization | Available as per shaker model |

Applications of PU Strips in Oil & Gas Drilling

Onshore drilling rigs

Offshore drilling platforms

Solids control systems

Oil-based, water-based & synthetic mud operations

Exploration, development, and workover drilling

A PU strip for shale shaker is essential wherever consistent shaker performance and long screen life are required.

Advantages of Polyurethane PU Strips Over Conventional Materials

| Feature | PU Strip | Rubber | Metal |

|---|---|---|---|

| Vibration Absorption | Excellent | Moderate | Poor |

| Abrasion Resistance | High | Medium | Low |

| Screen Protection | Excellent | Fair | None |

| Service Life | Long | Medium | Short |

| Fluid Sealing | Excellent | Moderate | Poor |

Why Choose Petropath PU Strips?

Our Strengths:

Compatibility with all major shale shaker brands

Custom PU strips for metal-backed and special screens

Consistent quality and precise fitment

Reliable supply and technical support

Other Shale Shaker Screen Sealing & Support Products by Petropath

1. Screen Gasket

A screen gasket is installed between the shale shaker screen and the shaker basket to create a tight, leak-free seal. It prevents drilling fluid bypass, reduces vibration damage, and improves overall solids separation efficiency. Screen gaskets are essential for maintaining consistent shaker performance under high flow rates.

2. Rubber Gasket for Shale Shaker Screen

The rubber gasket for shale shaker screen provides flexible sealing and effective vibration cushioning. It protects screen frames from continuous shaker motion and reduces wear caused by dynamic loads. This gasket is ideal for general drilling applications requiring reliable sealing and cost-effective performance.

3. Shaker Screen Gasket

A shaker screen gasket is specifically designed for shale shaker applications where strong sealing and vibration resistance are critical. It improves screen stability, minimizes fluid leakage, and supports efficient solids control in demanding drilling environments.

4. Seal Strip / Rubber Seal Strip for Shaker Screen

The seal strip for shaker screen, also known as a rubber seal strip, is installed along screen edges and between adjacent screens. It enhances sealing efficiency, prevents fluid loss, and reduces mud dilution, making it an important accessory in high-performance solids control systems.

5. Compression Strip for Shaker Screen

A compression strip for shaker screen ensures uniform pressure distribution across the screen surface. It minimizes screen movement during operation, improves fitment, and significantly extends screen service life, especially in high-G shale shaker applications.

6. Retainer Rubber for Shaker Screens

Retainer rubber for shaker screens is used in screen retention systems to securely hold screens in position. It prevents screen shifting, reduces vibration-related damage, and supports consistent shaker operation under heavy solids loading.

7. Hook Strip Screen Gasket

The hook strip screen gasket is designed for hook strip-type shale shaker screens. It provides reliable sealing and cushioning at the hook edges, protecting both the screen and shaker basket from wear, deformation, and vibration damage.

8. Pyramid Screen Gasket

A pyramid screen gasket is engineered to match the profile of pyramid-type shaker screens. It ensures proper sealing, reduces stress on screen frames, and improves solids separation efficiency by maintaining stable screen positioning.

9. Frame Gasket

The frame gasket is installed between the screen frame and shaker deck to prevent metal-to-metal contact. It enhances vibration absorption, protects structural components, and contributes to long-term shaker and screen integrity.

10. Natural Rubber (NR) Screen Gasket

Natural Rubber (NR) screen gaskets offer excellent elasticity and vibration damping. They are suitable for standard drilling operations where flexibility, sealing performance, and cost efficiency are required.

11. Nitrile Rubber (NBR) – Oil Resistant Screen Gasket

The NBR screen gasket is specially formulated for oil-based and synthetic drilling fluids. It provides superior oil resistance, durability, and long service life, making it ideal for demanding oilfield applications.

12. Neoprene (CR) – Vibration Resistant Rubber Gasket

Neoprene (CR) rubber gaskets deliver excellent vibration resistance, weather stability, and moderate oil resistance. They are well-suited for shale shaker systems requiring consistent performance under continuous dynamic loading.

Why Choose Petropath for Shale Shaker Sealing Solutions?

Key Advantages:

Complete range of sealing & support products

Multiple material options: PU, NR, NBR, Neoprene (CR)

Custom sizes for OEM and non-standard screens

Proven performance in harsh drilling conditions