Introduction

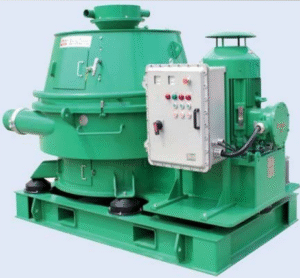

What is a Drilling Agitator?

Importance of Drilling Agitators

1. Preventing Solids Settling

Drilling fluids are loaded with additives like barite, bentonite, and polymers. If left stagnant, these solids sink, leading to uneven mud properties. A mud pit agitator ensures continuous mixing, eliminating sedimentation and safeguarding consistent fluid performance.

2. Maintaining Fluid Properties

A drilling fluid agitator maintains vital mud properties, reducing the risks of wellbore collapse, excessive drag, and equipment wear. Consistent viscosity and density directly translate to smoother drilling and reduced operational costs.

3. Enhancing Mixing Efficiency

During fluid preparation, a mixing agitator guarantees that all additives are thoroughly blended. This results in superior mud performance, fewer mixing errors, and shorter preparation time.

Advanced Features:

At Petropath Fluids India, we integrate innovation into every design. Our systems offer:

Variable Speed Control – Enables operators to adjust agitation intensity to match mud properties.

Corrosion-Resistant Materials – Built to withstand harsh drilling environments for longer service life.

Automated Monitoring Systems – Provides real-time data for performance optimization.

These features ensure reliability, efficiency, and extended equipment lifespan.

Real-World Applications

Our drilling agitators have delivered proven results in both onshore and offshore projects.

Offshore Case Study – A customized drilling agitator improved mud stability and prevented costly downtime.

Onshore Project – Variable-speed mud agitators reduced impeller wear, optimized fluid mixing, and enhanced drilling efficiency.

With these results, clients have achieved lower maintenance costs, better drilling control, and overall operational success.

Decades of expertise in drilling fluid management

Customizable our solutions for varied drilling conditions

Proven reliability in global onshore and offshore projects

Environmentally responsible engineering and design

Our solutions are built to deliver uninterrupted performance, making them an indispensable part of modern drilling operations.

Thanks!