Introduction

Understanding the Role of a High-Pressure High-Temperature Aging Cell

Robust Construction for Extreme Conditions

Precision and Compatibility in HPHT Mud Testing

Applications Across Drilling Fluid Laboratories

Static and dynamic aging tests of drilling muds

Evaluation of HPHT fluid stability under simulated downhole conditions

Performance testing of drilling fluid additives

Monitoring rheological and chemical property changes after aging

Supporting R&D and QA/QC programs in drilling fluid development

These applications make the equipment a critical component of any HPHT mud testing laboratory focused on performance optimization and risk reduction.

Key Advantages for Laboratory Professionals

Durable stainless steel design ensures long service life

Handles extreme pressure and temperature without compromise

Repeatable and reliable test results for confident decision-making

API-compliant design suitable for regulated testing environments

Low maintenance requirements with easy-to-replace seals and components

These advantages translate into improved testing efficiency and reduced operational downtime.

Safety and API Compliance

Optional Accessories and Customization

Pressure gauges (0–3000 psi) for precise monitoring

Safety relief valves for enhanced protection

Clamp assemblies for secure test setups

Replacement O-rings for routine maintenance

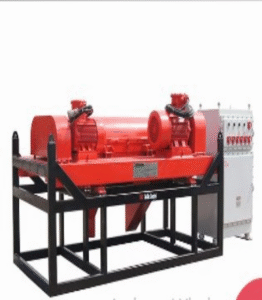

Roller ovens for complete HPHT aging systems

Custom configurations and spare parts are also available to extend equipment lifespan and maintain consistent testing performance.

Great site, i recommend it to everyone ArbSwap