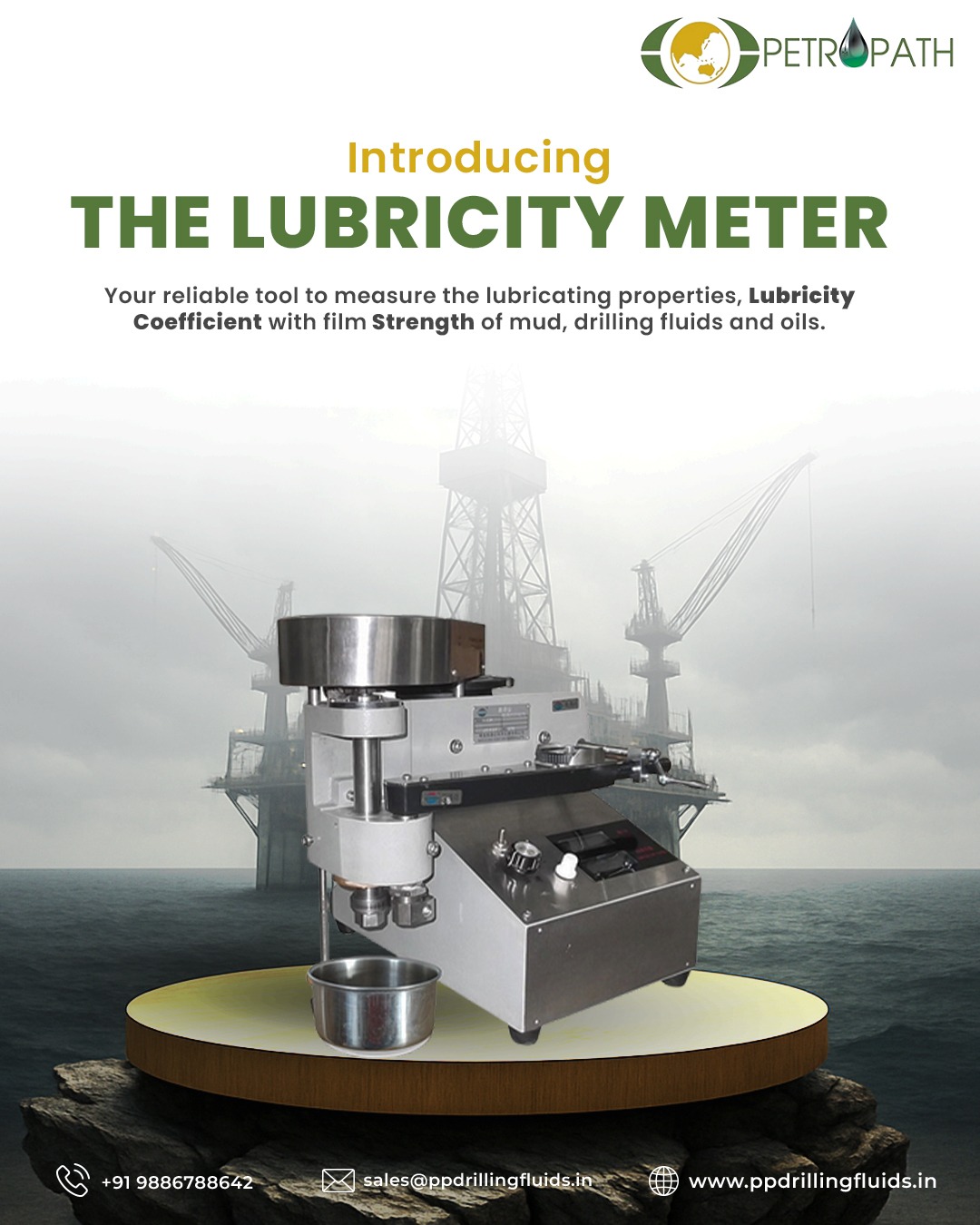

Lubricity Meter for Drilling Fluid Testing – Petropath Lubricitimeter

What is a Lubricity Meter?

The device helps measure:

Lubricity coefficient – an indicator of how slippery or effective the drilling fluid is.

Film strength – the ability of the fluid to maintain a protective barrier between metal surfaces.

Torque and drag values – critical data for optimizing drilling operations.

Key Terms Explained

Why is Film Strength Important in Drilling Fluid?

Why Choose Petropath’s Lubricity Meter???

Key advantages include:

📏 High-precision measurements of lubricity, film strength, and coefficient of friction.

🔧 Robust build for reliable use in both laboratory and field environments.

🛠️ Simple calibration and low maintenance, saving time and costs.

🌍 Trusted worldwide, with proven use across major oilfields in Saudi Arabia, UAE, and Kuwait.

Applications

The versatility of our Lubricity Meter makes it suitable for a wide range of applications, including:

Testing OBM (Oil-Based Mud) and WBM (Water-Based Mud) for lubricity.

Monitoring film strength during drilling operations.

Evaluating the performance of lubricants and additives.

Reducing mechanical wear on drilling tools.

Enhancing drilling efficiency by optimizing lubricity coefficient values.

Boost Your Drilling Efficiency with Accurate Mud Lubricity Testing

- Select optimal mud formulations.

- Minimize risks of equipment failure.

- Improve drilling accuracy and speed.

- Extend the life of drilling tools.