Pitless Drilling Closed Loop System: Smart & Sustainable Drilling Waste Management

Introduction

What Is Pitless Drilling?

Commitment to Environmental Responsibility

Why the Pitless Drilling Closed Loop System Is Essential

The Pitless Drilling Closed Loop System offers multiple operational and environmental advantages that make it essential for modern drilling projects:

- Economical Waste Management System – Reduces disposal, land acquisition, and water procurement costs

- Eco-Friendly Operations – Minimizes environmental footprint through controlled waste handling

- Instant PCB Approvals – Simplifies regulatory processes and accelerates project timelines

- No Land or Area Issues – Eliminates the need for large waste pits

- 100% On-Site Operations – All processes are performed at the drilling location

- Water Conservation – Enables effective reuse of treated water

- Zero Mud Waste – Maximizes drilling fluid recovery

- Useful Dried Cuttings – Converts waste into reusable by-products

These benefits make pitless drilling an ideal solution for companies focused on efficiency, compliance, and sustainability.

Closed Loop Drilling System: The Core Advantage

At the heart of pitless drilling lies the closed loop drilling system, a fully integrated waste containment and recycling process. This system ensures that drilling fluids and cuttings never come into direct contact with the surrounding environment.

Key Advantages of the Closed Loop System

Cost Efficiency – Lower waste disposal and water replacement expenses

Environmental Safety – Prevents soil and groundwater contamination

Operational Flexibility – Suitable for restricted and remote locations

Regulatory Compliance – Meets stringent environmental and PCB standards

By implementing a Pitless Drilling Closed Loop System, operators achieve long-term cost savings while maintaining uninterrupted drilling performance.

Mobile Effluent Treatment Plant (ETP) with RO Technology

Effective water management is critical in upstream oil and gas operations. Petropath Fluids India Pvt. Ltd. complements its pitless drilling services with Mobile Effluent Treatment Plants (ETP) integrated with Reverse Osmosis (RO) technology.

These mobile units efficiently treat drilling wastewater, sludge, and produced water, making it suitable for reuse in multiple applications.

Benefits of Mobile ETP with RO Technology

Environmental Protection – Reduces wastewater discharge

Produced Water Reuse – Safely recycles water generated during drilling

Improved Oil Recovery – Treated water can be used for injection

Regulatory Compliance – Ensures treated water meets quality standards

Cost Savings – Reduces freshwater dependency and operational costs

This advanced water treatment solution supports sustainable drilling while enhancing overall project economics.

Petropath’s Integrated Drilling Waste Management Services

With decades of industry expertise, Petropath Fluids India Pvt. Ltd. offers end-to-end drilling waste management services tailored to modern oil and gas operations.

Our Core Solutions Include:

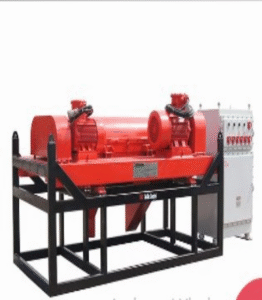

Pitless Drilling Closed Loop System

Comprehensive Drilling Waste Management

Mobile Effluent Treatment Plants with RO Technology

PCB-Compliant Operations

Environmentally Responsible Drilling Practices

By integrating pitless drilling, closed loop systems, and advanced water treatment, Petropath helps operators achieve operational excellence with minimal environmental impact.