Strategic Overview of Pitless Drilling Solutions

Understanding Pitless Drilling: A Closed-Loop Drilling System

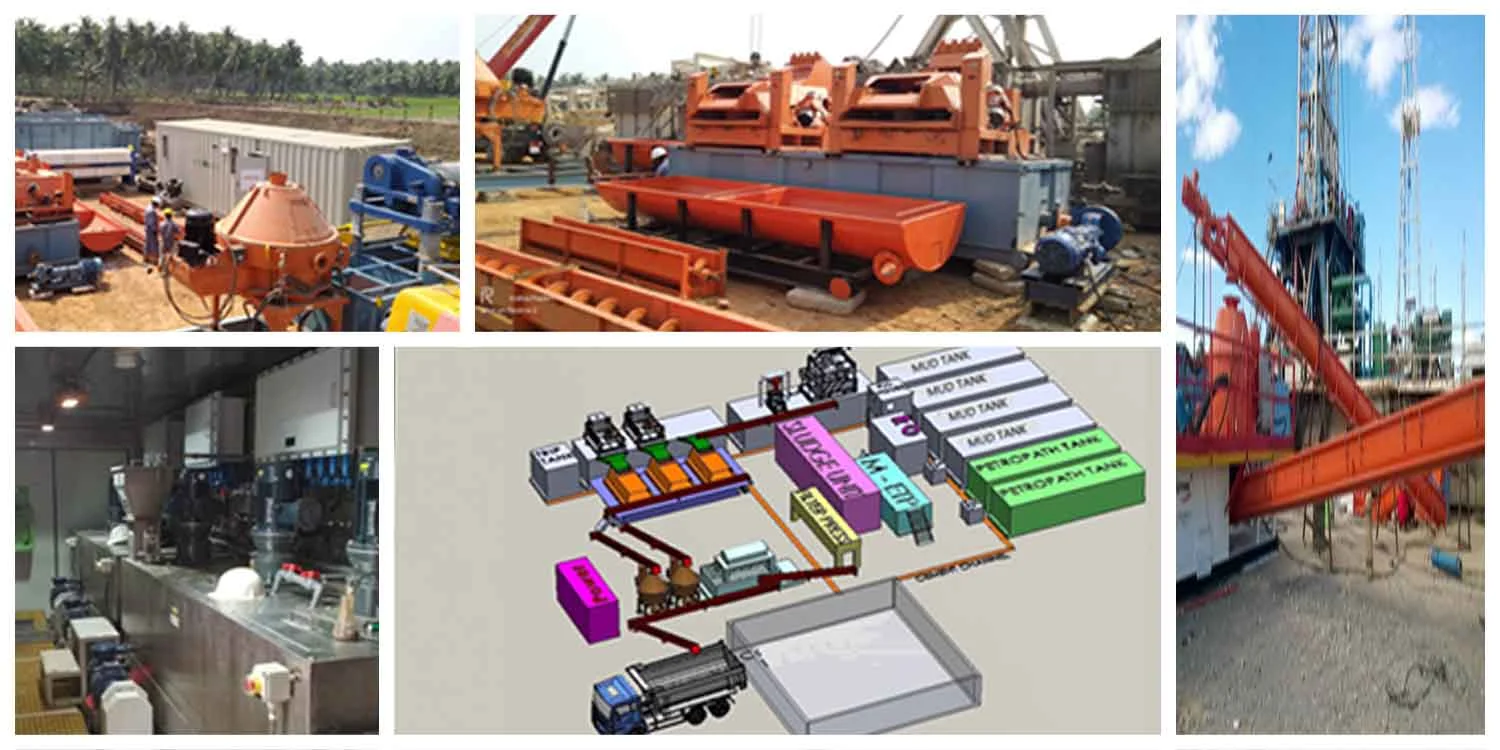

Petropath Pitless Drilling Solutions: System Capabilities

Key capabilities include:

Fully contained closed-loop configuration with zero pit requirement

High-performance solids control equipment such as shale shakers, desanders, desilters, and decanter centrifuges

Modular, skid-mounted design for rapid mobilization and minimal site footprint

Optimized drilling fluid recovery to reduce fresh water and chemical consumption

Seamless integration with effluent treatment plants and drilling waste management solutions

These capabilities allow operators to maintain full control over drilling fluids and waste streams while improving operational reliability.

Operational Workflow

- Drilling fluids return from the wellbore to surface steel tanks

- Solids are separated through multi-stage solids control equipment

- Cleaned drilling fluids are reconditioned and recirculated into the well

- Drill cuttings are safely contained for treatment, transport, or compliant disposal

Environmental Performance and Sustainable Drilling Operations

- Elimination of soil, groundwater, and surface water contamination risks

- Significant reduction in fresh water consumption through effective fluid reuse

- Lower waste volumes and reduced disposal requirements

- Strong alignment with ESG goals and sustainable field development strategies

HSE Excellence and Environmental Compliance Drilling

HSE and compliance benefits include:

Cleaner, safer, and more organized wellsite conditions

Reduced handling of drilling waste and contaminated fluids

Designed to meet stringent local and international environmental regulations

Strong audit readiness for regulatory inspections and operator reviews

Business Value

Business benefits include:

Lower long-term operational and waste management costs

Faster mobilization and demobilization compared to pit-based systems

Improved HSE metrics and reduced compliance-related delays

Strong acceptance by regulators, NOCs, and international operators

Petropath Fluids: A Trusted Partner

Why partner with Petropath Fluids:

Experienced technical teams with global project exposure

Custom-designed closed-loop drilling systems

Integrated services covering drilling fluids, waste management, and ETP solutions

Strong commitment to safety, reliability, and operational excellence