Horizontal Directional Drilling Equipment

In today’s fast-paced world, efficiency is key. Whether it’s in our daily lives or in large-scale construction projects, finding ways to maximize efficiency can save time, money, and resources. When it comes to underground construction projects, such as laying pipelines or cables, horizontal directional drilling (HDD) equipment plays a crucial role. In this article, we’ll explore how you can make the most out of your HDD equipment to ensure optimal efficiency and productivity.

Table of Contents

| Sr# | Headings |

|---|---|

| 1 | What is Horizontal Directional Drilling (HDD)? |

| 2 | The Components of HDD Equipment |

| 3 | Understanding the Drilling Process |

| 4 | Factors Affecting Efficiency |

| 5 | Tips for Maximizing Efficiency |

| 6 | Importance of Proper Maintenance |

| 7 | Advancements in HDD Technology |

| 8 | Environmental Considerations |

| 9 | Safety Measures |

| 10 | Conclusion |

1. What is Horizontal Directional Drilling (HDD)?

Horizontal Directional Drilling, commonly known as HDD, is a trenchless method used to install underground pipes, conduits, and cables with minimal disruption to the surface. Unlike traditional excavation methods that require digging trenches, HDD involves drilling a pilot hole from the surface to the desired endpoint, then enlarging the hole to accommodate the utility.

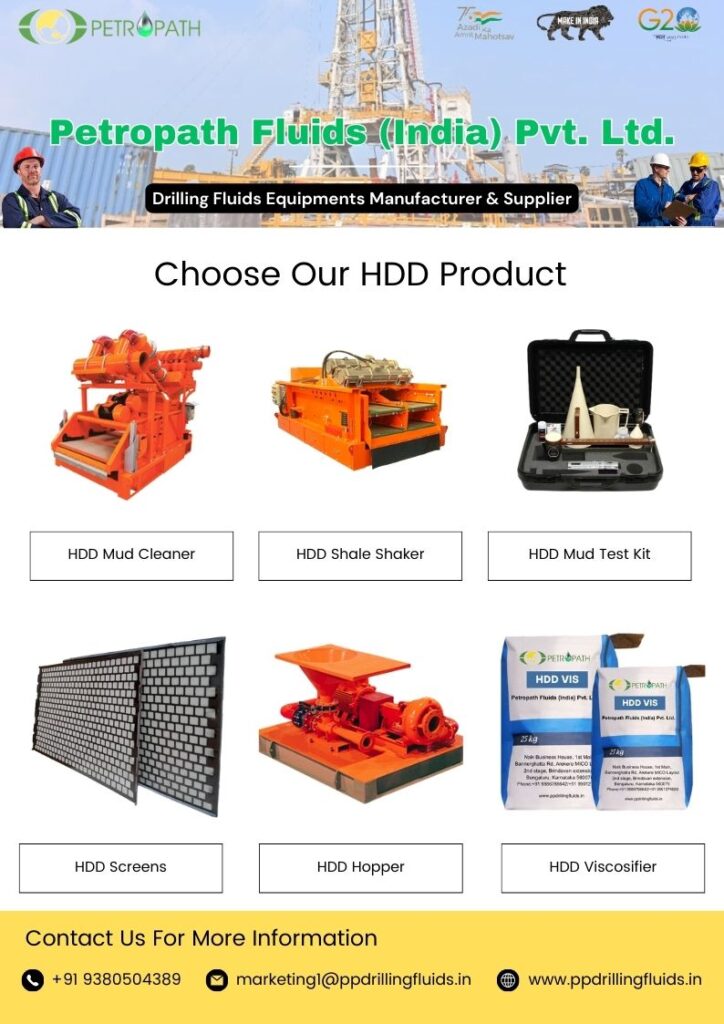

2. The Components of Horizontal Directional Drilling Equipment

HDD Rig: The heart of the operation, the HDD rig is responsible for drilling the pilot hole and pulling the product pipe back through the hole.

Drill Pipe: Hollow pipes connected to the drilling rig used to transmit drilling fluid and provide strength and stability to the drill string.

Reamer: Attached to the end of the drill string, the reamer enlarges the pilot hole to the required diameter to accommodate the product pipe.

Tracking Equipment: Utilized to monitor the location and depth of the drill head underground, ensuring precision during drilling.

3. Understanding the Drilling Process

The HDD process begins with locating and marking the entry and exit points for the drill. Once the setup is complete, the drilling rig is positioned at the entry point, and the pilot hole is drilled using a specialized drill bit. After reaching the exit point, the hole is enlarged to the desired diameter using progressively larger reamers. Finally, the product pipe is pulled back through the enlarged hole, completing the installation.

4. Factors Affecting Efficiency

Soil Conditions: The type of soil encountered during drilling can significantly impact efficiency. Hard, rocky soil may slow down progress, while softer soil allows for faster drilling.

Obstacles: Underground obstacles such as rocks, roots, and existing utilities can hinder the drilling process and require additional time and effort to overcome.

Equipment Performance: The condition and capabilities of the HDD equipment play a crucial role in efficiency. Well-maintained, high-quality equipment can operate more smoothly and quickly than outdated or faulty machinery.

5. Tips for Maximizing Efficiency

- Proper Planning: Thoroughly survey the site and plan the drilling process in advance to anticipate and mitigate potential challenges.

- Regular Maintenance: Keep HDD equipment well-maintained and serviced to ensure optimal performance and prevent breakdowns.

- Utilize Technology: Take advantage of advanced tracking and guidance systems to enhance precision and efficiency during drilling operations.

6. Importance of Proper Maintenance

Regular maintenance of HDD equipment is essential to ensure smooth and efficient operation. This includes routine inspections, lubrication, and replacement of worn parts. Neglecting maintenance can lead to costly downtime and repairs, as well as compromised safety during drilling operations.

7. Advancements in HDD Technology

Advances in HDD technology have led to improved efficiency, accuracy, and safety in underground drilling projects. From advanced tracking systems to more powerful drilling rigs, these innovations continue to push the boundaries of what is possible in trenchless construction.

8. Environmental Considerations

HDD offers significant environmental benefits compared to traditional excavation methods. By minimizing surface disturbance and reducing the need for large-scale excavation, HDD helps preserve natural habitats, minimize soil erosion, and protect sensitive ecosystems.

9. Safety Measures

Safety is paramount in any construction project, and HDD is no exception. Implementing proper safety protocols, providing adequate training to personnel, and using high-quality safety equipment are essential to prevent accidents and injuries during drilling operations.

10. Conclusion

In conclusion, maximizing efficiency with horizontal directional drilling equipment requires careful planning, proper maintenance, and utilization of advanced technology. By following best practices and prioritizing safety, HDD operators can achieve optimal results and minimize downtime, ultimately saving time, money, and resources.

FAQs (Frequently Asked Questions)

1. How deep can horizontal directional drilling go?

Horizontal directional drilling can reach depths of several hundred feet, depending on the capabilities of the drilling equipment and the geological conditions of the site.

2. Is horizontal directional drilling environmentally friendly?

Yes, horizontal directional drilling is considered environmentally friendly compared to traditional excavation methods due to its minimal surface disturbance and reduced impact on natural habitats.

3. What types of utilities can be installed using HDD?

HDD can be used to install a wide range of utilities, including water and sewer lines, telecommunications cables, electrical conduits, and natural gas pipelines.

4. How long does it take to complete an HDD project?

The duration of an HDD project varies depending on factors such as the length and complexity of the installation, soil conditions, and environmental considerations. Small-scale projects may be completed in a matter of days, while larger projects could take several weeks or even months.

5. Is horizontal directional drilling safe?

When proper safety protocols are followed and equipment is well-maintained, horizontal directional drilling is considered a safe method of underground construction. However, as with any construction activity, there are inherent risks that must be managed to ensure the safety of workers and the public.