Mud Cleaners for Efficient HDD Operations

Petropath Fluids India Pvt. Ltd. stands at the forefront of innovation in the drilling industry. As a leading manufacturer, they specialize in crafting premium quality mud cleaners that redefine efficiency and reliability. Let’s delve into why choosing Petropath for your mud cleaner needs is a decision that enhances your drilling operations.

Mud cleaners play a crucial role in the world of Horizontal Directional Drilling (HDD). These innovative systems help maintain drilling fluid quality, improve efficiency, and reduce costs. In this article, we’ll explore what mud cleaners are, their benefits, and how they contribute to successful HDD projects.

What Are Mud Cleaners?

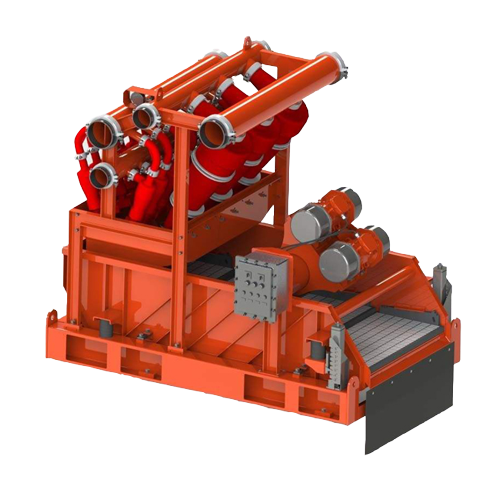

Mud Cleaners: Also known as mud reclaimers or mud recycling systems, these specialized equipment pieces are designed to clean and recycle drilling fluids during HDD operations. They remove solid particles from the drilling slurry, allowing the reuse of valuable base fluids. Here’s how they work:

- Two-Stage Separation Process: Mud cleaners use a two-stage separation process. First, hydrocyclones perform primary separation, directing the underflow onto a shale shaker. The shale shaker further screens out dry solids.

- Effective for Both Weighted and Unweighted Fluids: Whether you’re dealing with weighted or unweighted drilling fluids, mud cleaners remain equally effective. By recycling used drilling slurry, they help lower fluid expenses and disposal costs.

Mud Cleaner Overview

- Purpose: The mud cleaner is designed to remove solid particles (drill cuttings) from the drilling fluid (mud) during HDD operations.

- Components: It consists of several key components:

- Hydrocyclones: These are mounted over a vibrating screen (shale shaker). Hydrocyclones separate solids from the mud based on particle size.

- Shale Shaker: This vibrating screen sieves out larger particles, allowing the weighted fillers (such as barite) to remain suspended in the mud.

- Desanders: Larger hydrocyclones (typically 10″ in diameter) remove coarser sand-sized particles.

- Desilters: Smaller hydrocyclones (typically 4″ in diameter) remove finer silt-sized solids.

- Function: The mud cleaner ensures that drill cuttings are efficiently filtered out while maintaining the necessary mud properties for drilling.

Technical Parameters and Specifications

- Capacity: Mud cleaners are available in various capacities (measured in cubic meters per hour or GPM).

- Example models:

- PP24-MC12: Capacity of 120 m³/h (528 GPM)

- PP24-MC13: Capacity of 240 m³/h (1056 GPM)

- PP24-MC14: Capacity of 360 m³/h (1584 GPM)

- Example models:

- Desander Size: Typically 10 inches.

- Screen Size: The shale shaker’s vibrating screen is sized according to the specific drilling operation. Screen Variance: Finer screens are used for lighter muds, while slightly coarser screens are employed for weighted muds to prevent filtering out the weighted fillers.

Use Case and Benefits

- Use Case:

- Mud cleaners are deployed during HDD operations to maintain drilling fluid quality.Deployment During HDD Operations: Mud cleaners are deployed during HDD operations to maintain drilling fluid quality.

- Efficiency in Cuttings Removal: They are especially useful in situations where drill cuttings need to be removed efficiently.

- Benefits:

- Improved Drilling Efficiency: By removing solid particles, mud cleaners enhance drilling efficiency and reduce downtime caused by clogged equipment.

- Reduced Environmental Impact: Properly filtered mud minimizes environmental contamination.

- Cost Savings: Efficient solids control leads to longer equipment lifespan and cost savings.

- Premium Quality from Petropath Fluids India Pvt. Ltd.: Petropath Fluids India Pvt. Ltd. manufactures and supplies top-quality mud cleaners, ensuring reliable performance in HDD projects.

Sizing and Selection

Choosing the right mud cleaner size is essential for optimal performance. Consider the maximum fluid flow rate down the drill string. For instance:

- If you’re using a Vermeer D100x140 S3 Navigator HDD drill with a maximum flow of 230 gallons per minute (gpm), the Vermeer R250C reclaimer (capable of cleaning up to 250 gpm) is an ideal match.

- For higher fluid volumes, the Vermeer R600T reclaimer can handle up to 600 gpm. This model is designed to keep pace with maxi rigs using high-pressure mud pumps.

The Petropath Advantage

1. Uncompromising Quality

Petropath’s commitment to excellence is unwavering. Their mud cleaners are meticulously engineered using cutting-edge technology and high-grade materials. Here’s what sets them apart:

- Robust Construction: Petropath mud cleaners withstand the rigors of demanding drilling environments. Whether it’s rocky terrains or soft soils, these machines consistently deliver performance.

- Precision Engineering: Each component undergoes rigorous testing to ensure optimal functionality. From hydrocyclones to screens, Petropath leaves no room for compromise.

2. Efficiency Redefined

When time is money, Petropath’s mud cleaners shine:

- Two-Stage Separation: Petropath mud cleaners employ a two-stage separation process. The hydrocyclones remove coarse particles, while the shale shaker screens out finer solids. This efficient design minimizes downtime and maximizes productivity.

- Fluid Recycling: By efficiently cleaning drilling fluids, Petropath mud cleaners reduce wastage. Cost Savings and Environmental Impact: Reusing treated slurry not only saves costs but also minimizes environmental impact.

3. Tailored Solutions

Petropath understands that every drilling project is unique. That’s why they offer customizable mud cleaner solutions:

- Size and Capacity: Whether you’re working on a small-scale project or a large HDD operation, Petropath provides mud cleaners in various sizes. Choose the one that aligns with your specific requirements.

- Compatibility: Petropath mud cleaners seamlessly integrate with different drilling rigs and systems. Their versatility ensures smooth workflows.

4. Responsive Support

Petropath doesn’t just sell equipment; they build lasting partnerships. When you choose Petropath, you gain:

- Technical Expertise: Their team of engineers and technicians provides prompt assistance. From installation to maintenance, Petropath stands by your side.

- Availability: Need spare parts or troubleshooting? Petropath’s responsive customer support ensures minimal downtime.

Conclusion

In the world of drilling, Petropath Fluids India Pvt. Ltd. shines as a beacon of reliability. When efficiency matters, trust Petropath mud cleaners to elevate your drilling experience.