When it comes to Horizontal Directional Drilling (HDD), one of the most critical pieces of equipment used in the drilling process is the shale shaker screen. These screens play a crucial role in the separation and filtration of drilling fluids, ensuring that the operation runs smoothly and efficiently. At Petropath Fluids India Pvt. Ltd., we specialize in manufacturing customized shale shaker screens that are tailored to meet the unique needs of HDD drilling. Whether you’re looking for Mongoose & NOV screens, Wave screens, or Kemtron screens, we have the right solution for your project.

In this blog post, we will discuss the different types of shale shaker screens, their applications, and why Petropath is the best choice for your HDD shale shaker screen needs. If you’re looking for high-quality shale shaker screens, contact us today at www.ppdrillingfluids.in or reach out to us via email at marketing@ppdrillingfluids.in

What are Shale Shaker Screens?

A shale shaker screen is a mesh screen installed in the shale shaker, a key piece of equipment in the solids control system during drilling operations. The main function of a shale shaker screen is to filter and separate large solids (like cuttings) from drilling fluid (or mud) so that the fluid can be reused and the drilling operation can continue efficiently.

Without a reliable shale shaker screen, your drilling fluid can become contaminated, leading to increased wear on your drilling tools and potential operational delays.

Types of Shale Shaker Screens

At Petropath, we offer a wide range of shale shaker screens to meet the specific needs of HDD drilling. Each type of screen is designed to work in various environments and with different drilling conditions.

1. Mongoose & NOV Shale Shaker Screens

The Mongoose and NOV screens are some of the most popular types of shale shaker screens in the market. They are known for their high filtration efficiency, durability, and ability to handle tough drilling conditions. These screens are typically used in oil and gas drilling, HDD, and other large-scale projects.

2. Wave Screens

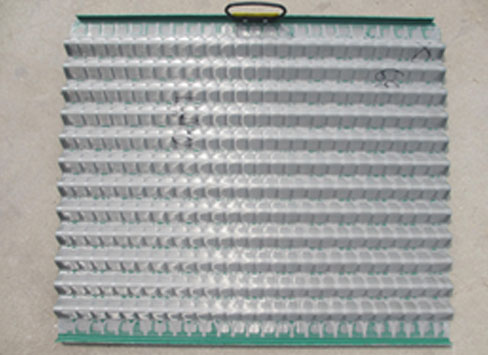

Wave screens are designed to offer superior filtering capacity and better fluid handling. The wave design increases the screen area, allowing for more fluid to pass through while efficiently separating the solids. This makes wave screens ideal for high-volume HDD projects where efficient fluid recycling is critical.

3. Kemtron Shaker Screens

Kemtron shaker screens are renowned for their excellent performance and long lifespan. These screens are commonly used in drilling applications where high levels of solids removal are required. They are compatible with Kemtron shale shakers and other industry-standard systems, ensuring that your drilling fluid remains clean and reusable.

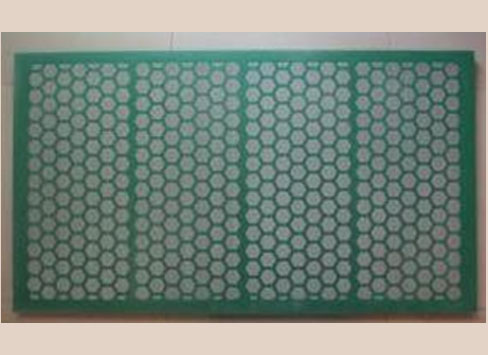

4. Customized Metal Screens

Petropath also specializes in customized metal screens that are specifically designed to meet the demands of HDD drilling. These screens are made from durable materials and are engineered to withstand tough drilling conditions while ensuring maximum fluid filtration. Customized screens can be tailored to fit your specific shaker model and drilling needs.

Petropath’s Customized HDD Shale Shaker Screens

At Petropath Fluids India Pvt. Ltd., we understand that every drilling project is unique, which is why we offer customized shale shaker screens tailored to your specific requirements. Our HDD shale shaker screens are designed to:

- Maximize fluid recovery: Our screens help you recover more drilling fluid, reducing waste and operational costs.

- Enhance solids control: Efficient separation of solids ensures that your drilling fluid remains clean, improving overall operational efficiency.

- Improve screen longevity: Manufactured from high-quality materials, our screens are built to last, even in the toughest conditions.

For more information on our customized HDD shale shaker screens, visit our website at www.ppdrillingfluids.in.

Applications of Shale Shaker Screens in HDD

Shale shaker screens are essential for various Horizontal Directional Drilling (HDD) and oil and gas applications. They are widely used in:

1. Horizontal Directional Drilling (HDD)

In HDD drilling, shale shaker screens play a vital role in maintaining the cleanliness and efficiency of drilling fluids. Proper filtration ensures smooth operations, minimizes downtime, and enhances the overall productivity of the project.

2. Oil and Gas Drilling

Shale shaker screens are also used extensively in oil and gas drilling, where the proper separation of solids from drilling mud is crucial for the efficiency and safety of the operation.

3. Utility and Pipeline Installation

During the installation of underground utilities and pipelines, shale shaker screens help ensure that the drilling fluid remains uncontaminated, allowing for efficient and precise drilling.

Why Choose Petropath for Your Shale Shaker Screens?

Petropath has built a reputation as one of the leading shale shaker screen manufacturers in India. Here’s why we’re the right choice for your drilling needs:

1. High-Quality Materials

We use only the highest-quality materials to manufacture our screens, ensuring that they offer long-lasting performance even in harsh drilling conditions.

2. Customization Options

We offer customized shale shaker screens that are tailored to your specific drilling requirements, ensuring that you get the best fit and performance.

3. Competitive Pricing

At Petropath, we offer high-performance shale shaker screens at competitive prices, providing excellent value for your investment.

4. Industry Expertise

With years of experience in manufacturing screens for HDD and other drilling operations, we have the expertise to provide you with the best solutions.

To learn more about our products or to request a quote, visit www.ppdrillingfluids.in or contact us directly at marketing@ppdrillingfluids.in or call +91 9380504017.

Frequently Asked Questions (FAQs)

1. What is the purpose of a shale shaker screen in drilling?

The primary purpose of a shale shaker screen is to filter and separate large solids from drilling fluid, ensuring that the fluid can be reused during the drilling process.

2. What are the different types of shale shaker screens available?

Common types of shale shaker screens include Mongoose & NOV screens, Wave screens, Kemtron screens, and customized metal screens.

3. Can Petropath customize shale shaker screens for HDD?

Yes, Petropath specializes in creating customized HDD shale shaker screens tailored to your specific drilling needs.

4. What is the lifespan of a shale shaker screen?

The lifespan of a shale shaker screen depends on the material used and the drilling conditions, but Petropath’s screens are designed for long-lasting performance.

5. How can I purchase shale shaker screens from Petropath?

You can order our shale shaker screens by visiting our website www.ppdrillingfluids.in or by contacting us at marketing@ppdrillingfluids.in or +91 9380504017.

Conclusion

Shale shaker screens are a critical component in ensuring the success of your HDD drilling operations. Whether you need Mongoose & NOV screens, Wave screens, or customized HDD screens, Petropath offers the best shale shaker screens designed to deliver performance and durability.

For top-quality shale shaker screens that meet your drilling requirements, visit Petropath Fluids India Pvt. Ltd. and explore our full range of products.